Why walk…

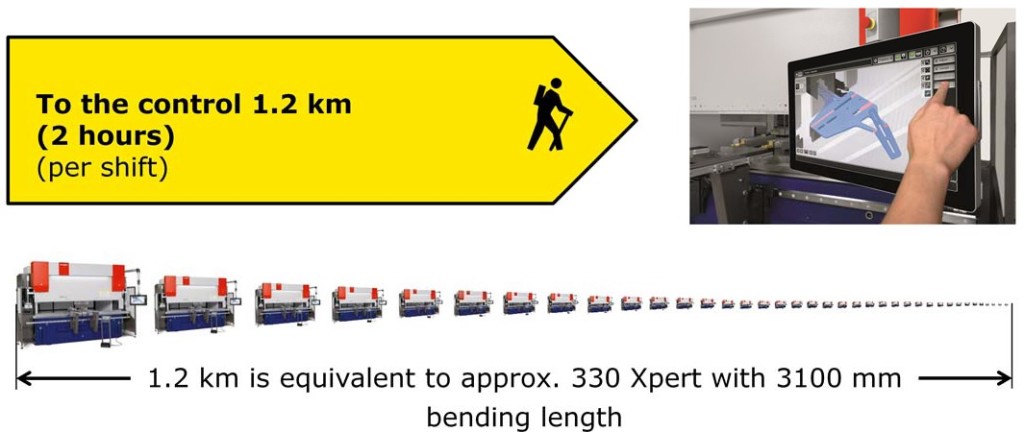

During an average shift, a machine operator “hikes” more than 1 km to the control unit to make corrections or similar adjustments.

This calculation is based on approximately 8 to 12 job changes per shift and a bending lenght of 3100 mm.

The distance is equivalent to roughly 330 lined-up Xpert 150/3100 machines.

This equals approximately 2 hours per shift or 15 minutes per hour, during which the operator’s time is taken up by walking.

During these 2 jours, the operator coild be producing additional parts.

… when you can talk?

Talk prdouctivity – reduction of non-productive time and unnecessary walking distances.

The voice control allows the 17 most important operations to be input directly by voice via the headset.

e.g.:

- Adjustment of angles, upper beam position and speed

- Opening and closing of clamps

- Navigating through the ByVision Bending menu