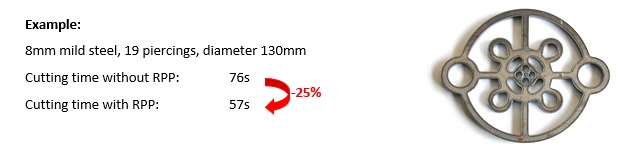

Regulated Pulsed Piercing (RPP)

Customer benefits:

- Average reduction of piercing time of 30%

- Very fast and reliable, regulated piercing without “boiling” or “explosions”, regardless of the sheet metal quality, i.e.

– regardless of the sheet metal temperature

– regardless of the exact sheet metal composition

- Reduced contamination of nozzle and lens

- Easy operation (less parameters)

Technical Information

The new Regulated Pulsed Piercing (RPP) comprises two main components

1. Laser Piercing Monitor

The Laser Piercing Monitor analyses the reflected light in order to

- enable an automatic calculation of the best parameters to be used for the piercing process, i.i. automatic regulation of the optimal peircing parameter

- allow cutting as soon as the material has been pierced through, i.e. immediate stop of piercing when the material has been perforated

Laser Piercing Monitor

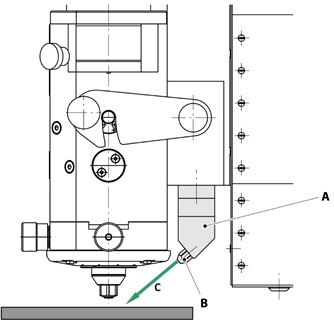

2. Piercing Jet

While piercing, nitrogen (C) is blownin the direction of the piercing ponit on the sheet. The nitrogen is fed by the Piercing Jet (A) with an exchangeable nozzle (B). The Piercing Jet leads to a cooling of the piercing point on the sheet.

Piercing Jet